in 57 countries of the world

equipment

In 2018, Power Machines announced the development of its own technology for manufacturing gas turbines with a capacity of 65 MW and 170 MW as a part of the upgrade program for thermal power plants in Russia. Renewal for gas turbine unit production is a landmark project not only for the company, but for the whole country.

The company is implementing the project with support from the Ministry of Industry and Trade of the Russian Federation to ensure energy and technological independence for the state. To implement this task, the design bureau was re-established; at present, the prototype gas turbine units GTE-65 F-class and GTE-170 E-class are in production. The company is also developing hydrogen energy technologies and is working on the creation of a gas turbine capable of operating on methane-hydrogen mixtures.

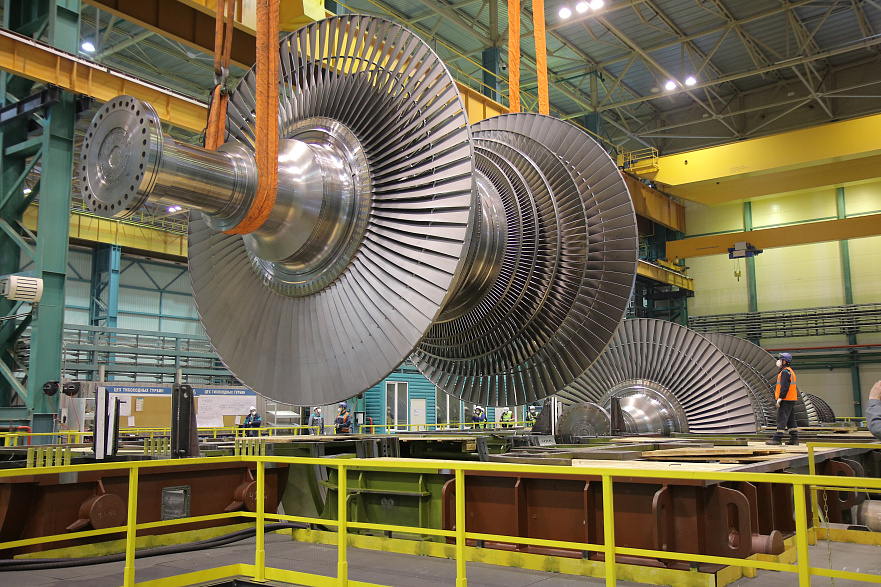

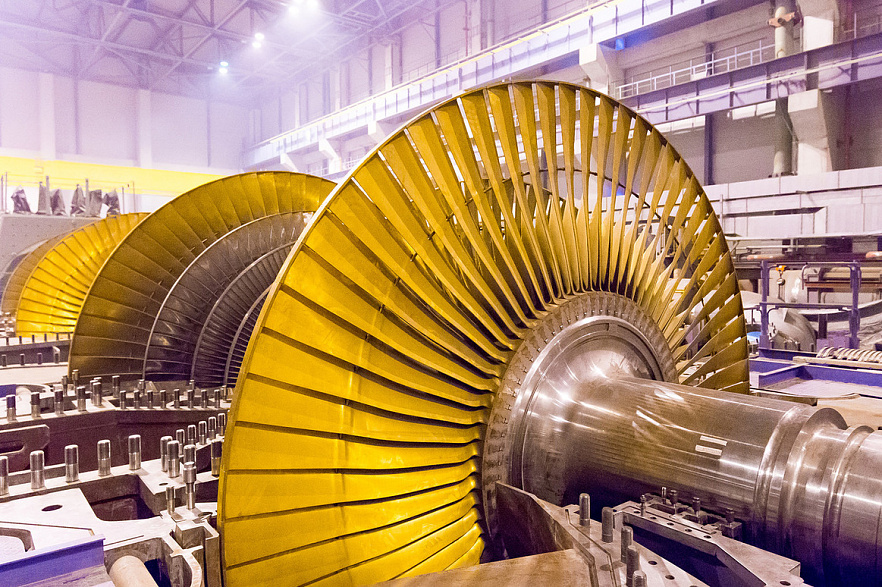

Based on its experience creating heavy-duty full-speed steam turbines and achieving advanced scientific achievements, Power Machines developed and manufactured the first half-speed turbine unit in Russia with a capacity of 1255 MW. Today the half-speed turbine is considered one of the most promising in the world – the main assembly characteristics will allow future machines to be created based on its design, the use of which will be possible in a turbine plant with a unit capacity in the range of 1600-1800 MW.

The full-speed steam turbine unit for nuclear power plants, complete with a 1200 megawatt generator, is another unique technology in our portfolio. Power Machines is the only company in the world that has reached a capacity of 1200 MW with a full-speed version. This allows us to offer a more compact and cost-effective solution for the nuclear power industry than what foreign manufacturers do. The most powerful in Russia and the world's first 3+ generation power units Novovoronezh NPP-2 and Leningrad NPP-2 are equipped with this.

The Center for Hydrogen Technology is a new line of business for Power Machines, established to master technologies for storing, transporting, producing, and consuming hydrogen. The company is researching technologies that can create plants in the fields of electrolysis, hydrogen storage systems, steam reformation, and pyrolysis. The ultimate goal is to become a supplier that offers a full range of engineering solutions for hydrogen production and consumption.

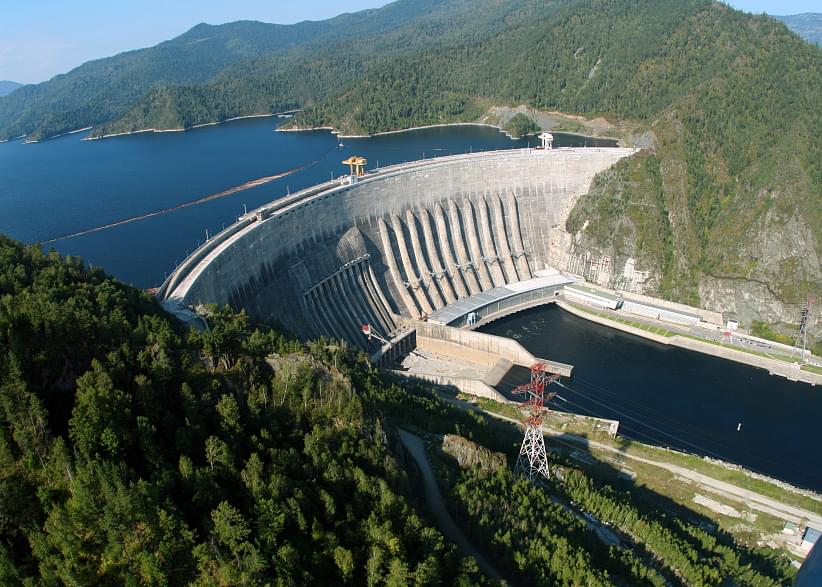

Power Machines manufactured and delivered the main power equipment to restore the Sayano-Shushenskaya HPP - ten hydraulic turbines with hydro generators with a capacity of 640 MW each and excitation systems for them. Currently, the largest hydroelectric power plant in the country is equipped with new, modern equipment with improved performance and meeting all the requirements for reliability and safety. The service life of new units has been increased to 40 years, while the maximum efficiency of the hydraulic turbine is 96.6%. Particular attention is paid to the safety of new equipment operation.

The enterprises that are part of Power Machines stood at the origins and rapid growth of the Russian energy sector. Here, the first sets of Russian turbine and generator equipment were made, and unique technologies were created, which are now widely used in the global energy industry. Thanks to our knowledge of the features of almost all energy facilities in Russia, we offer our customers the most efficient and optimal solutions.

The predictive diagnostics system is a new, advanced product that our team has developed. This project allows early detection of defects and thereby ensuring generating equipment that is reliable and efficient. The predictive diagnostics system makes it possible to bring to a new level not only reliability management of strategically important assets - the generating equipment, but also efficiency management across the plant as a whole. We plan to equip all technical equipment that we produce with a predictive diagnostics system.

We have implemented integrated projects for the country's shipbuilding industry, including the nuclear icebreaker fleet.

The world's first nuclear-powered icebreaker "Lenin" was equipped with our propulsion electric motors. Subsequently, the largest Soviet series of “Project 10520” nuclear icebreakers, and its best representative, Arktika, became the first ship in history to reach the North Pole and was equipped with these propulsion motors. Today, the research and production capabilities of "Power Machines", as well as its own testing site, allow for integrated projects for the Russian shipbuilding industry to be implemented.

Power Machines is a supplier of a large range of power and electrical equipment for mining engineering. We manufacture electric traction drives for BELAZ mining dump trucks, electric motors, DC machines, and packaged electric drives for mining excavators. All our equipment is reliable to the highest degree due to employing advanced hardware components.